HYDRON SE230A

Aqueous-based, alkaline defluxing for semiconductor electronics

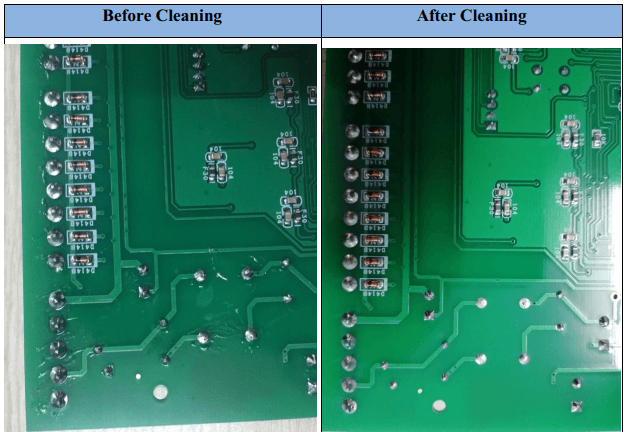

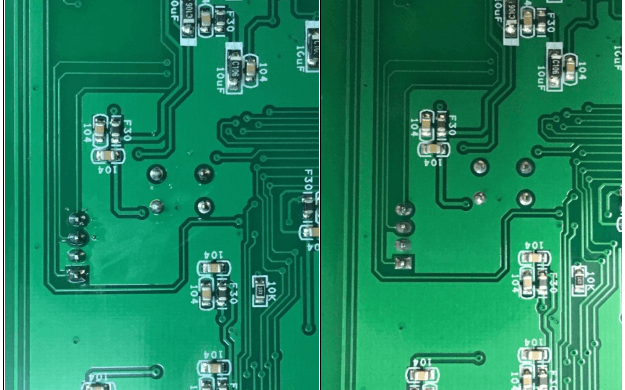

HYDRON® SE 230A is an aqueuos-based, single-phase cleaning agent specifically developed for the use in dip tank processes. It removes flux residues from a wide range of semiconductor electronics, such as leadframes, discrete devices, power modules, power LEDs, flip chips, and CMOS following the die attach process. The cleaning agent provides excellent deoxidiation of copper substrates for subsequent processes such as wire bonding and molding.

Advantages of HYDRON® SE 230A compared to other cleaners:

- Features very low surface tension, ideal for cleaning capillary spaces, i.e. underneath low stand-off components.

- Exhibits a high level of material compatibility with sensitive materials such as copper, aluminum and nickel.

- Retains activated copper surfaces over an extended period of time without risk of reoxidation

- Easily rinsed with DI-water yielding residue-free surfaces, Low ordor

Area of Specific Application:

- Alkaline

- Defluxing of semiconductor electronics

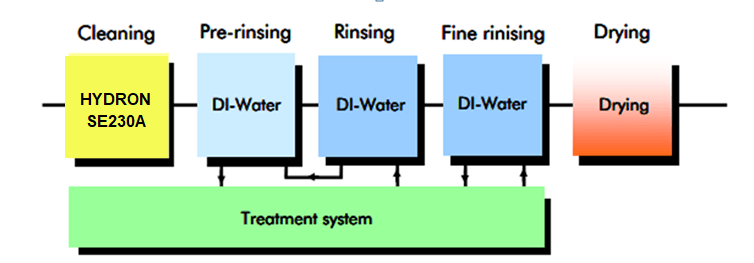

Process:

- Ultrasonic

- Spray-under-immersion

- Centrifugal cleaning

Contamination:

- Flux residues

- Solder paste (unsoldered)

- SMT or conductive adhesives

CUSTOMER

Vietnamese

Vietnamese 한국어

한국어 简体中文

简体中文