For reflow ovens and wave solder systems, water-based

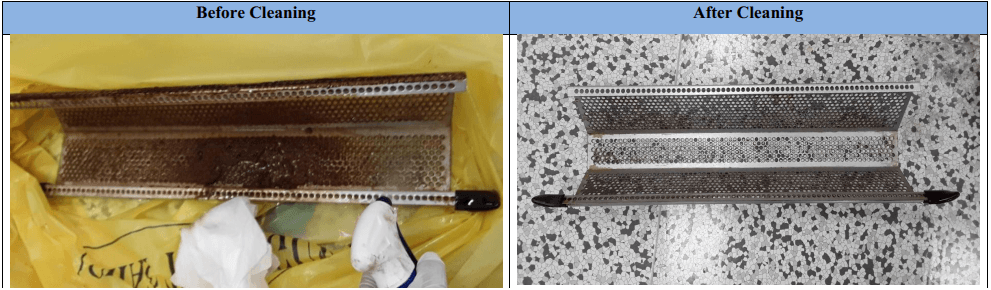

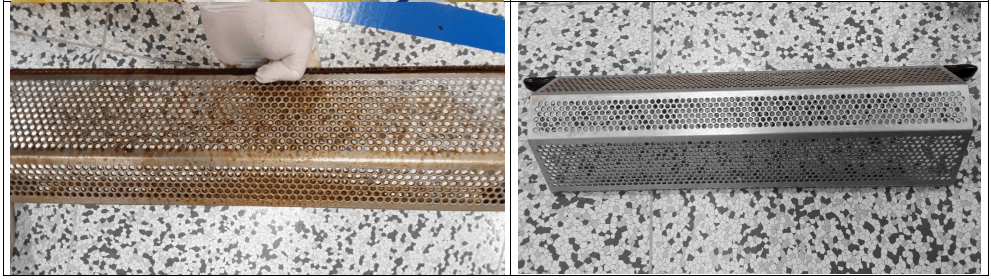

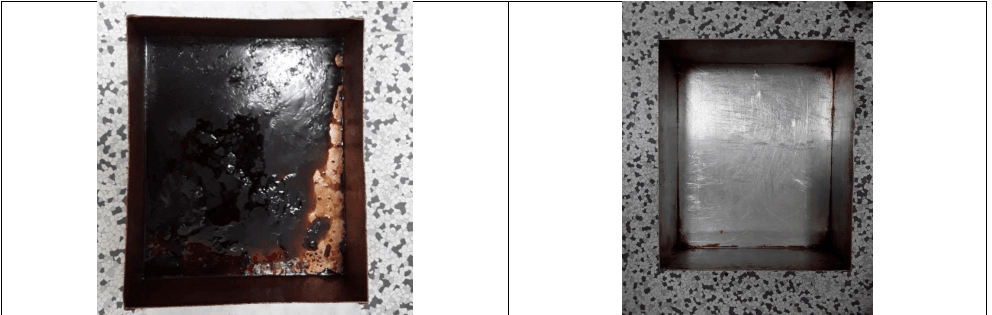

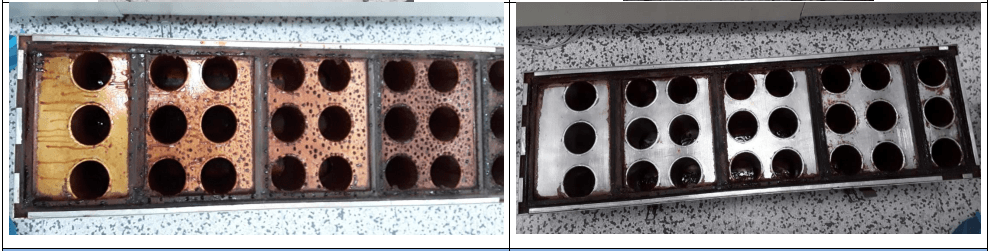

Based on the MPC® Technology, VIGON® RC 101 was specifically developed to remove all types of baked-on flux residues from reflow and wave solder equipment. It reliably removes re-condensated fluxes and emissions from assemblies.

Advantages compared to other cleaners:

- Has no flash point and therefore can be applied directly onto cold or warm surfaces (30 – 40 °C / 86 – 104 °F)

- The medium does not contain any ingredients, which could leave residues on the oven surfaces. This avoids harmful condensations on the assembly surfaces after restarts

- Due to the short soaking time, a quick and efficient cleaning process can be achieved and long machine downtimes can be avoided

Area of Specific Application:

- Reflow oven cleaning

- Wave solder machine cleaning

- Tool cleaning

Process:

- Manual Cleaning

- Automated cleaning of conveyor fingers in wave solder ovens

Contamination:

- Baked-on fluxes

- Fumigation contamination

- MPC Technology

CUSTOMER

Vietnamese

Vietnamese 한국어

한국어 简体中文

简体中文